Lamella

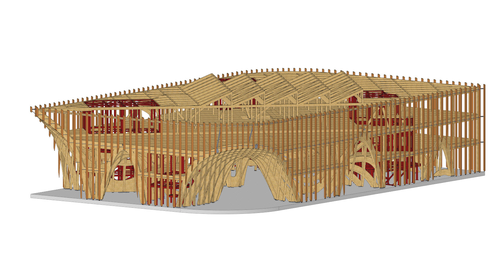

The vast majority of glulam specialists today are working with cadwork. The freedom you get in cadwork 3D and the geometric definition you can create for the elements is definitely a good starting point for the workflow for many companies.

HOW DOES IT WORK ?

Based on the final geometry of a free-form glulam beam, cadwork will automatically calculate the laminate distribution, define the clamping and display all the laminates while taking into account the specified manufacturing conditions. The results are tailored to the individual needs of each company and they enable the management of a complete fabrication line. The representation and dimensions of the press locations are also automatic. Each laminate can be individually stretched and the rest will dynamically adapt itself to the actual or projected representation. When calculating, different parameters can be freely defined. From the choice of wood quality through the control of the glue application to the automatic positioning of the press and cylinders, you get a very complete machine file that can even position the presses automatically.